Overview

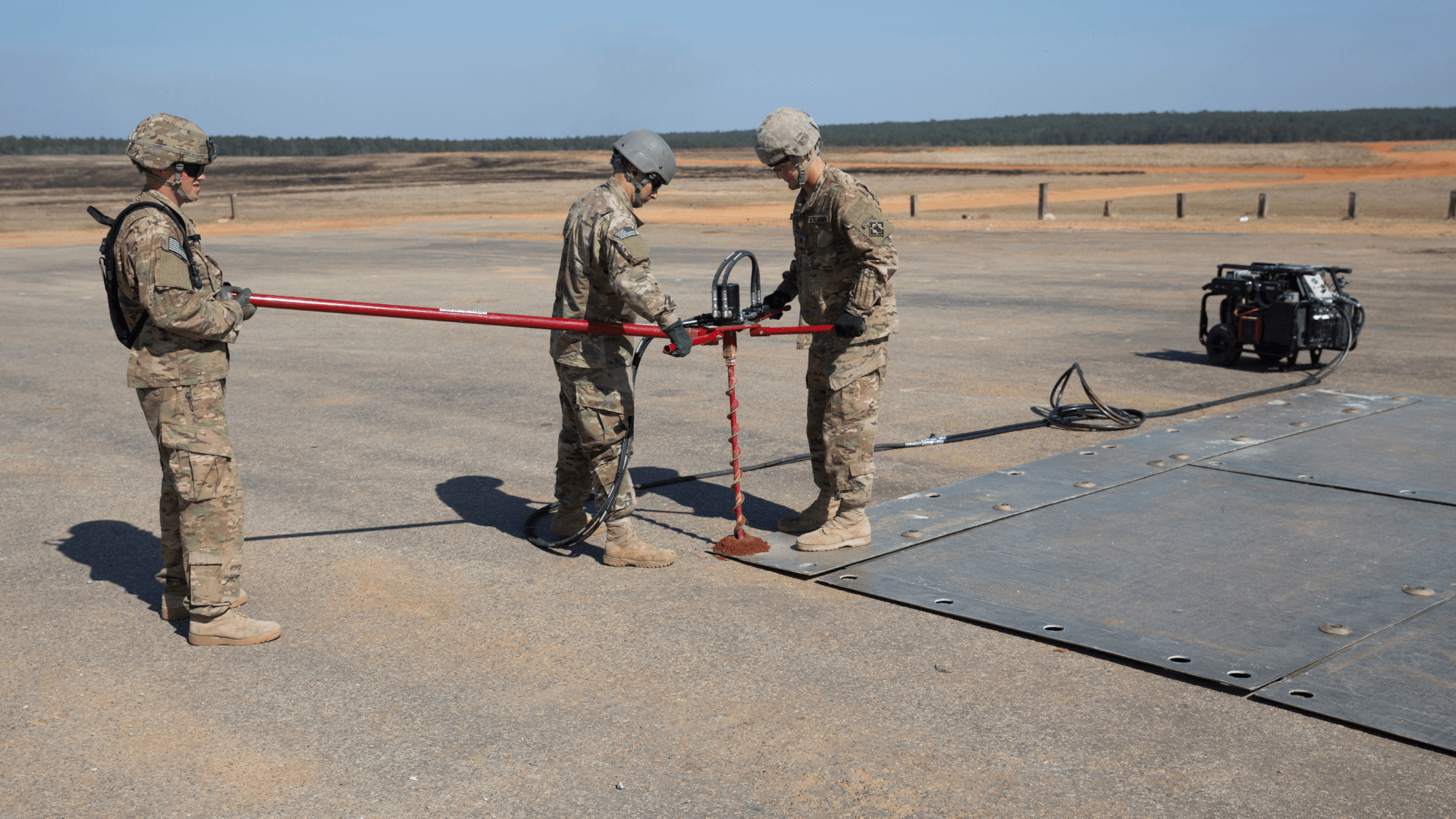

The U.S. Army Engineer Research and Development Center (ERDC) Geotechnical and Structures Laboratory (GSL) seeks to understand the range of commercially available ground anchoring systems and grout products for rapid airfield damage recovery.

This is a Request for Information (RFI) only and any response is not an offer. This RFI does not commit the Government to pay any costs incurred in preparation of a response or guarantee a contract.

Project Objective

ERDC seeks to identify what is currently commercially available that meets the minimum specifications provided below. Interested parties are invited to review the problem statements and project objectives related to grout materials for anchor/connections and ground anchor alternatives, and provide current capabilities that address the requirements for each opportunity below.

Problem Statement: This is a request for non-shrink or expansive grout materials to be rapidly mixed and cast by non-technical personnel for rapid airfield damage recovery anchorage techniques in stiff, non-rock base materials.

Project Objective: The objective is to understand and evaluate the range of commercially available grout products available which are suitable and can improve on the strength/pull-out bond of grouted anchors used in rapid airfield damage recovery.

Requirements: Candidate products should meet or exceed the threshold (minimum standard) listed herein. To demonstrate capabilities, please provide:

- Technical data sheets for products which validate performance claims.

- If including additional materials (i.e., admixtures or expanding agents), include the mix design or plan for combining the material with grouts.

There are several different requirements for these grout materials, including:

- Grouts must be rapid-set, achieving structural compressive strength (>2500 psi) in a maximum of two hours after casting.

- Grouts should be non-shrink, expansive, or be accompanied by another admixture/agent which can enhance non-shrink or expansive properties of the base grout.

- Materials must be fluid during the casting process.

- The mixing process must be simple enough that non-technical personnel can perform it.

- Shelf-life of products should be a minimum of six months and able to withstand warm ambient temperatures prior to use.

Problem Statement: This is a request regarding ground anchors that could be employed in asphalt concrete pavement systems as alternates to ground anchors currently employed. The current ground anchors may not be deployable in calcareous or dense granular foundation soils. Viable alternatives should be able to provide support in the range of the current design loads. They will also need to be used as-built or with only minor modifications to be employed in a rapid airfield damage recovery kit. These alternatives will need to use existing equipment with only minor alterations to be viable with the existing kit.

Project Objective: The objective is to understand and evaluate the range of commercially available ground anchoring systems. The results of this investigation will provide alternatives to the runway repair kit in geologic areas where the existing ground anchor system has deployment issues.

Requirements: Candidate products should meet or exceed the threshold (minimum standard) listed herein. To demonstrate capabilities, please provide:

- Technical data sheets for products which validate performance claims.

There are several different anchor requirements, including:

- The pull-out capacity of the anchors prior to 1 in. of displacement should exceed 12,000 lbs.

- Should be capable of accepting a 5/8 inches number 11 threaded bolt at its head or be capable to accept this bolt with minor modifications.

- Maximum embedment depth should be no more than 5 ft and not less than 8 inches.

- These ground anchors should be installed through the use of hand tools requiring only hydraulic or electrical power.

- It is desired that these anchors be applicable over multiple foundation conditions but foundations consisting of medium to dense sand, gravel, or calcareous sand are of particular interest.

- It is not required but the capability to rapidly install and deploy these anchors is desirable.

Note: Submissions should NOT include confidential or proprietary details. Submissions may be shared with other ERDC teams if there is an apparent fit with other ERDC projects.

Expected Result

ERDC intends to use the information received to inform the acquisition strategy necessary to meet project goals. Offerors submitting responses meeting the minimum specifications may be hosted for a virtual pitch. Submissions may be shared as appropriate with other ERDC parties.

Notional Project Schedule

Grout Materials for Anchor/Connections

| June 28, 2024 | Submissions open |

| July 15, 2024 | Question period ends |

| August 7, 2024 | Submissions close at 5:00 pm CT |

| July 2024 | ERDC completes review of submissions/virtual pitches hosted by ERDCWERX, if necessary |

Ground Anchor Alternatives

| June 28, 2024 | Submissions open |

| July 15, 2024 | Question period ends |

| August 7, 2024 | Submissions close at 5:00 pm CT |

| August 2024 | ERDC completes review of submissions/virtual pitches hosted by ERDCWERX, if necessary |

*If needed; dates may vary to accommodate project team and participant availability.

How to Participate

All submissions received by the deadlines stated in this announcement, by 5:00 pm CT, will receive full consideration.

All items submitted in the capability statement shall comply with U.S. Export regulations including, but not limited to, the requirements of the Arms Export Control Act, 22 U.S.C. § § 2751-2794, including the International Traffic in Arms Regulation (ITAR), 22 C.F.R. § 120 et seq.; and the Export Administration Act, 50 U.S.C. app. § 2401-2420.