Overview

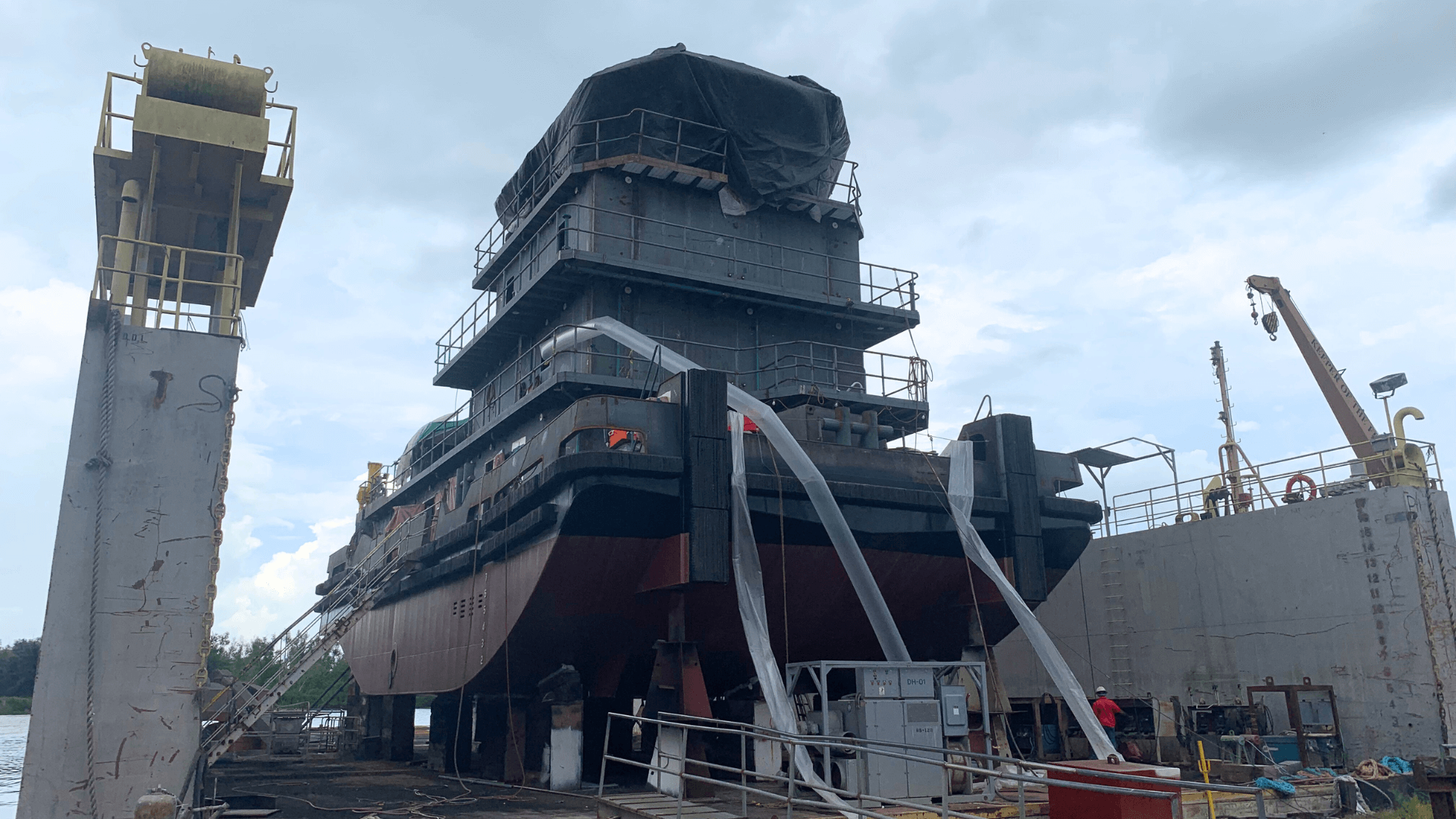

The U.S. Army Engineer Research and Development Center (ERDC)’s Information Technology Laboratory (ITL) seeks to identify solutions capable of assisting personnel with visual inspection in confined spaces on marine vessels.

Project Objective

Working with the U.S. Army and other government partners, ERDC is interested in Remotely Operated Vehicles or other robotic tools to enter a confined space on vessels to perform some or all visual inspection functions (e.g., visual inspection of welds/paint coverage, paint thickness readings, NDT steel thickness readings, identifying small leaks, etc.). Any robotic confined space inspection tools developed to aid in vessel inspections, may have direct application in other U.S. Army Corps of Engineers (USACE) (and beyond) confined space inspection requirements such as bridge inspections, steel lock and dam inspections, hydropower dam inspections, etc.

Background and Operational Scenarios

USACE inspectors are tasked with QA/QC inspections of USACE vessels throughout the construction process while being built at various shipyards. USACE personnel must inspect all welds, paint, and fabrication, many in confined spaces, to make sure the contract requirements are being met. There are countless voids and confined spaces that are extremely difficult, if not impossible, to be accessed by a human. Access is extremely limited via small diameter circular or oval shaped hatches and internal “lightening holes” requiring human inspectors to crawl through narrow passages and mazes of structural plates, I-beams, stiffeners, pipes, cabling, holding tanks (potable water, fuel, oil, DEF, sewage), etc. that severely restrict maneuverability.

Requirements

ERDC’s Information Technology Laboratory (ITL) invites white papers that introduce robotic platforms and similar technologies that could aid in visual inspection of confined spaces. Robotic tools should aid the inspection of confined spaces, thereby reducing human exposure to hazards. Partial solutions may be considered. Proposed solutions can be an advanced idea or can build on existing technology. All potential solutions will be considered.

Dimensions: Solutions must be able to enter and maneuver in confined spaces and navigate around structural elements. Physical constraints are quantified as follows.

- Manhole entry minimum size is 18 inches in diameter.

- There are numerous structural elements such as I-beams with heights ranging from 4-5 inches to 12 or more inches and widths typically 2-5 inches.

- Bulkhead holes are a minimum of 12 inches in diameter with 16×24 inch ovals typical.

Note: Submissions not strictly conforming to and accommodating the listed dimensional requirements may be considered since there is variety in the hull geometries.

Operation: The solution should be easily operable by the existing inspection staff, positioned at a safe standoff from hazardous conditions—ideally above deck and not within the confined space—with limited training and without the need for dedicated certifications. Real-time video to aid operation may be necessary since the tool will operate beyond line of site. Autonomous or semi-autonomous solutions will also be considered. The enclosed steel structures will present a challenge for RF, GPS, or other wireless communication and navigation technologies and should be accounted for. The solution should have sufficient battery life to enter the space, inspect, then exit the space without manual intervention. A tether or umbilical connection for power and communication is also acceptable.

Sensing: The priority for sensing modality is high resolution video with appropriate onboard lighting. Real-time video is desirable but not strictly required if not needed for operation. Video should be recorded for off-line viewing. Various NDT sensors (e.g. paint and coating thickness) or other modalities (chemical vapor) may be desirable but are not a priority at this time. Flexible sensor payloads may be desirable.

Expected Result

Phase I: ERDC gains an understanding of the market, assesses the applicability of new and existing solutions for confined space inspections, and ascertains the experience and capability of the submitting parties. Down-selected parties will be considered for demonstration to stakeholders.

Phase II: Potential demonstration of proposed solutions at a shipyard with a vessel under construction, or a surrogate structure at an appropriate alternative facility.

Potential Demonstration Scenario: Confined space inspection

- Enter the space, collect high-resolution video, and exit the space without manual intervention.

Funding is not currently available for this project. Observations from the demo may be utilized to inform future inspection practices and equipment of various government partners.

Evaluation Criteria

Submissions will be evaluated based on the following criteria:

- Technical Merit – Feasibility and applicability of proposed solution

- Cost/Schedule – Preparedness and appropriateness of cost and schedule details cited

- Business Viability – Organizational capacity, years in operation, relevant specialties, and capabilities

- Prototype/Demo – Technology Readiness Level (TRL) and availability of this solution for demonstration

Submissions must be formatted as prescribed in the white paper template. Submissions should not include confidential or proprietary details. Submissions will be reviewed by ERDC/government subject matter experts and may be shared as appropriate with other ERDC parties.

Notional Project Schedule

Proposed project milestones include:

| December 6, 2024 | Project Announced, Submissions Open |

| January 13, 2025 | Question Period Ends, FAQ Document Finalized |

| January 21, 2025 | Submissions Close |

| March 2025 | Downselected Vendors Notified |

| Spring 2025 (TBD) | Demonstration of Proposed Solutions |

*If needed; dates may vary to accommodate project team and participant availability.

How to Participate

- Submit specific details by providing a white paper (download template)

- Review FAQs

- Once white paper is ready to submit, complete the submission form

Questions: Please send all technical and administrative questions using this form. Q&A will be updated periodically. It is the responsibility of the offeror to review Q&A prior to submitting.